Mechanical joint saddle fittings, PE saddle fittings, and electrofusion saddle fittings are all essential components in the construction industry. These fittings are used in the installation of pipes, valves, and other equipment used in water supply systems, gas pipelines, and other infrastructures.

One of the most significant advantages of mechanical joint saddle fittings, PE saddle fittings, and electrofusion saddle fittings is that they are incredibly durable and long-lasting. These fittings are built to withstand the toughest of conditions, ensuring that they remain operational for years to come. This is particularly important in the construction industry, where equipment failure can lead to costly repairs and downtime.

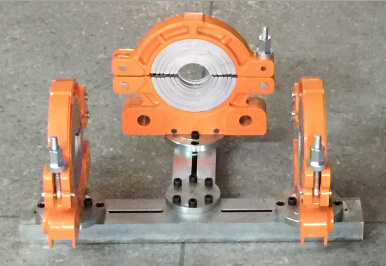

Mechanical joint saddle fittings, for example, are ideal for joining pipelines and other equipment where the joints may be subject to significant stress. These fittings are made of materials such as cast iron and ductile iron, which are known for their strength and durability. This makes them an excellent choice for installing pipes in areas where the pipes are exposed to heavy loads or high-pressure conditions.

PE saddle fittings, on the other hand, are made from high-density polyethylene (HDPE). This material is known for its strength and longevity, making PE saddle fittings an ideal choice for a wide range of applications in the construction industry. The high-density polyethylene material used in these fittings is resistant to corrosion, making it ideal for use in water supply systems, gas pipelines, and other high-performance applications.

Electrofusion saddle fittings are another innovative solution that is widely used in the construction industry. These fittings are made by welding together two HDPE pipes using an electrofusion machine. The resulting join is incredibly strong and reliable, making it an ideal choice for use in water and gas supply systems, sewer networks, and other demanding applications.

In addition to their durability and longevity, mechanical joint saddle fittings, PE saddle fittings, and electrofusion saddle fittings are also incredibly versatile. They are available in a range of sizes and configurations, making them suitable for a wide range of applications. This versatility makes them an ideal choice for contractors who need to install equipment in a variety of environments.

Another significant advantage of mechanical joint saddle fittings, PE saddle fittings, and electrofusion saddle fittings is that they are easy to install. These fittings can be installed quickly and easily, reducing the time and cost involved in the installation process. This can be particularly beneficial in large-scale construction projects where the cost of delays and downtime can quickly add up.

Moreover, mechanical joint saddle fittings, PE saddle fittings, and electrofusion saddle fittings are generally more cost-effective than traditional pipe joining methods. These fittings are typically more affordable to manufacture and install than other types of pipe fittings, making them an ideal choice for projects where cost is a significant factor.

CHUANGRONG is a leading manufacturer of mechanical joint saddle fittings, PE saddle fittings, and electrofusion saddle fittings. The company has been in business since 2005, and its products are known for their quality, durability, and reliability. CHUANGRONG also offers a range of other products, including HDPE pipes, fittings, and valves, PPR pipes, fittings, and valves, and PP compression fittings and valves.

In conclusion, mechanical joint saddle fittings, PE saddle fittings, and electrofusion saddle fittings are essential components in the construction industry. Their durability, versatility, and cost-effectiveness make them an ideal choice for a wide range of applications. As the construction industry evolves, it is clear that these innovative fittings will continue to play a vital role in the development of infrastructure around the world.