| Application: | Gas,Water,Oil Etc | Product Name: | Electrofusion HDPE Fittings Branch Saddle For Gas Supply PN16 SDR11 PE100 |

|---|---|---|---|

| Specification: | 63*32mm~315*90mm PE100 PN16 SDR11 | Standard: | EN 12201-3:2011,EN 1555-3:2010 |

| Port: | China Main Port | Material: | PE100 Virgin Raw Material |

Electrofusion HDPE Fittings Branch Saddle for Gas supply PN16 SDR11 PE100

Production Description of Electrofusion HDPE Branch Saddle

Electrofusion HDPE fittings are welded by electrofusion machine to connect HDPE pipes together: After electrofusion welding machine plug in electricity and turn on, The copper wire buried inserted in electric fuse HDPE fittings are heated and make HDPE melt, Which joint HDPE pipe and fittings well.

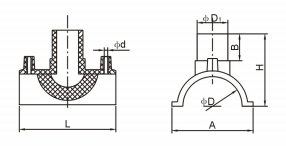

| pecifications φD×D1 | L mm | A mm | B mm | H mm | d mm |

| 63×32 | 110 | 100 | 45 | 80 | 4.7 |

| 90×63 | 145 | 155 | 80 | 145 | 4.7 |

| 110×32 | 145 | 160 | 80 | 145 | 4.7 |

| 110×63 | 145 | 160 | 80 | 145 | 4.7 |

| 160×63 | 190 | 230 | 100 | 185 | 4.7 |

| 163×90 | 190 | 230 | 100 | 185 | 4.7 |

| 200×63 | 190 | 235 | 110 | 185 | 4.7 |

| 200×90 | 190 | 235 | 115 | 195 | 4.7 |

| 250×63 | 190 | 300 | 125 | 195 | 4.7 |

| 250×90 | 190 | 300 | 125 | 195 | 4.7 |

| 315×63 | 190 | 300 | 115 | 195 | 4.7 |

| 315×90 | 190 | 300 | 115 | 200 | 4.7 |

1. Municipal water supply, gas supply and agriculture etc. 2. Commercial & Residential water supply 3. Industrial liquids transportation 4. Sewage treatment 5. Food and chemical industry 6. Replacement of cement pipes and steel pipes 7. Argillaceous silt, mud transportation 8. Garden green pipe networks

1. Municipal water supply, gas supply and agriculture etc. 2. Commercial & Residential water supply 3. Industrial liquids transportation 4. Sewage treatment 5. Food and chemical industry 6. Replacement of cement pipes and steel pipes 7. Argillaceous silt, mud transportation 8. Garden green pipe networks

| Test item | Standard | Conditions | Results | Unit |

| 1.Melt Flow Index | ISO1133 | 190°C & 5.0Kg 0.2-0.7 | 0.49 | g/10min |

| 2.Density | ISO1183 | @23°C ≥0.95 | 0.960 | g/cm3 |

| 3.Oxidation Induction Time | ISO11357 | 210°C >20 | 39 | Min |

| 4. Hydrostatic Pressure Test | ISO1167 | 80°C 165h, 5.4Mpa | Passed | |

| 5 Size Check | ISO3126 | 23°C | Passed | |

| 6 Appearance | Clean& Smooth | 23°C | Passed |

- The results according to test 1-3 are taken form the PE raw material supplier’s report.

- The results according to test 4-6 are taken from the internal test results of fittings sampled from the

- same batch as delivered fittings.

- Marking according EN 12201 – 3 and EN 1555 – 3.

- The pass/fail criteria are based on the requirements of the UNI EN 12201 and UNI EN 1555 standards.