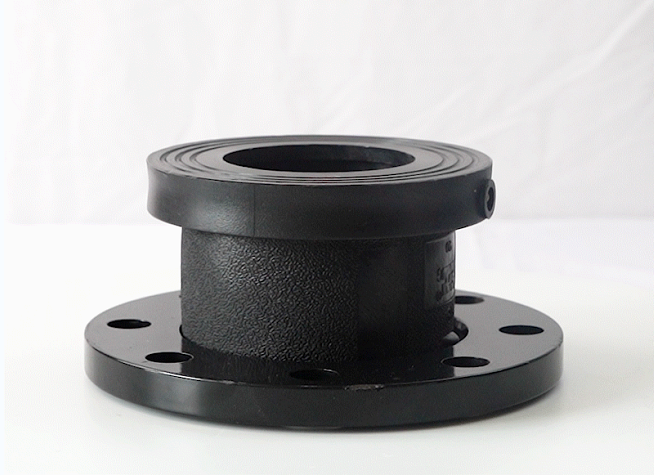

| Product Name: | HDPE Electrofusion Fittings Flange Adapter For Gas And Water Supply PN16 SDR11 PE100 | Connection: | Electrofusion |

|---|---|---|---|

| Standard: | EN 12201-3:2011,EN 1555-3:2010 | Material: | PE100 Virgin Raw Material |

| Technic: | Injection Molding | Application: | Gas,Water,Oil Etc |

lectrofusion isa method of joiningMDPE,HDPE and other plastic pipes using special fittings that have built-inelectric heating elements which are used toweldthe joint together.

Electrofusion HDPE fittings(Include electrofusion reducing tee, Elbow, Reducer, End cap, Stub end etc.) are welded by electrofusion machine to connect HDPE pipes together: The electrofusion welding machine plug in electricity and turn on, The copper wire buried inserted in electric fuse HDPE fittings are heated and make HDPE melt,Which jointHDPE pipe and fittings well.

P2:4.7 Pin(4.0 welded bySwitched adaptor) P3:Printed Parameters P4:Embedded copper wire 1)Fusion Pin Invented by fusion,the fusamtic pin provides a totally automatic method for ensuring the correct welding parameters are used.Within each fusamatic pin is resistor.When the electrofusion box is connected to the fitting,the fusamatic pin enables it to automatically identify the correct fusion time requited to make the joint.

All the operator has to do is press go. 2)Moulded-in welding paramet Manual welding parameters are moulded into the body of all fusion’s fitting.Information provided includes fitting size,material(PE80 or PE100),applicable pipe SDRs,weld parameters,and pressure ratings for gas and water applications.

3)Element&Stops

To promote joint quality,all elements are coated with polyethylene before being moulded into the fitting body.

All fittings have removable pipe stops.The stops ensure pipes cannot be inserted past the midpoint,but can be removed for use in,for example,repair situations.

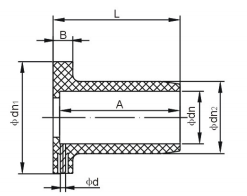

| Specifications φdn | Φdn1 | Φdn2 | L mm | A mm | B mm | Φd |

| 50 | 89 | 65 | 116 | 110 | 17 | 4.7 |

| 63 | 102 | 79 | 115 | 115 | 18 | 4.7 |

| 75 | 121 | 94 | 125 | 125 | 20 | 4.7 |

| 90 | 139 | 109 | 140 | 140 | 23 | 4.7 |

| 110 | 172 | 139 | 145 | 145 | 25 | 4.7 |

| 160 | 228 | 189 | 152 | 152 | 28 | 4.7 |

| 200 | 289 | 234 | 174 | 174 | 30 | 4.7 |

| 250 | 339 | 280 | 123 | 123 | 32 | 4.7 |

| 315 | 390 | 349 | 127 | 127 | 39 | 4.7 |

| 400 | 513 | 436 | 153 | 153 | 39 | 4.7 |