| Connection: | Flange | Name: | Dismantling Joint |

|---|---|---|---|

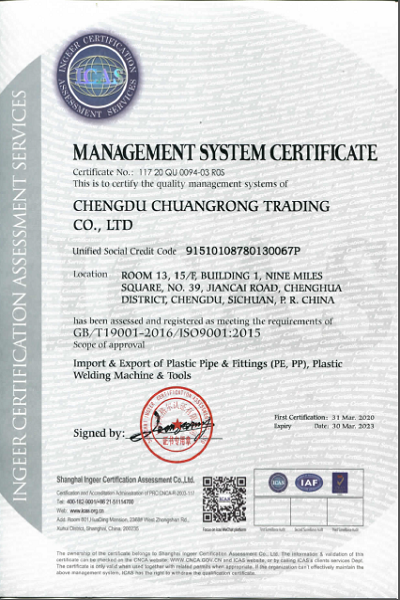

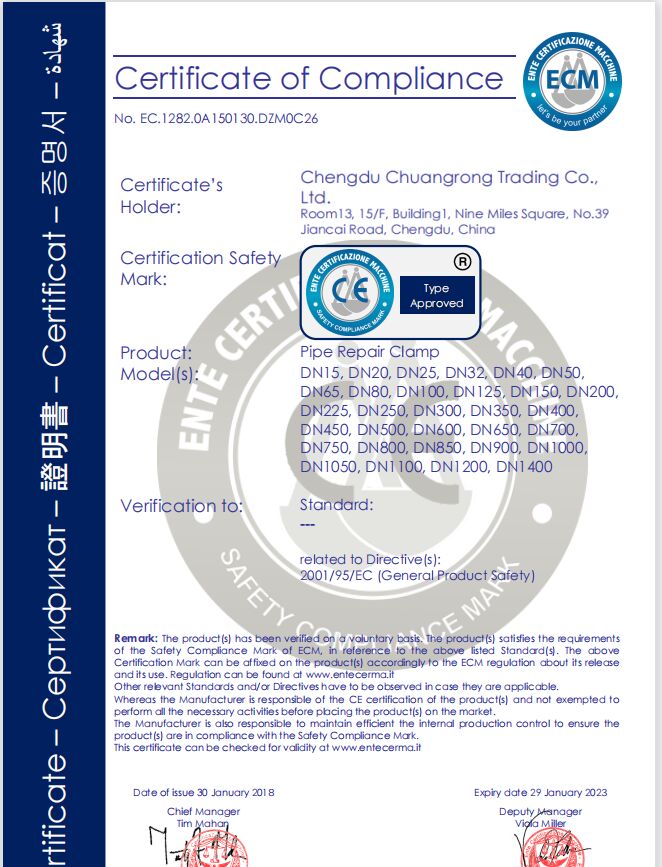

| Application: | Protable water, neutral liquids and sewage | Certificate: | ISO 9001:2008/CE/SGS/ |

| Features: | Corrosion resistant constructionStuds are located on every flange hole Tie rods are required from the upstream to downstream sides of the pipe equipment installation | Options: | Flange driling with BS or ANSI standardGD8.8, Stainless steel ,dacromet bolt Various coating Seal : NBR etc |

Material Body: Ductile iron grade 500-7/ 450-10 in accordance with ISO 1083 or 70-50-05/65-45-12 with ASTM A536 Gland: Ductile iron grade 500-7/ 450-10 in accordance with ISO 1083 or 70-50-05/65-45-12 with ASTM A536 Gasket: Rubber E. P. D. M. /SBR/NR in accordance with EN 681.1 T-BOLTS AND NUTS: Carbon steel grade 8.8/6.8/4.8 with dacromet coating/galvanization Self-restrained dismantling joints 1.Used to facilitate the dismantling or the reassembly of a flanged piece of equipment on a pipeline, and adjustable in length with considerable travel. 2.Simplify maintenance operations because the connection is self-anchored and there is no need for concrete anchor blocks. Dismantling joint for flanged butterfly valve 1.Facilitates dismantling and reassembly in situ on the pipeline when bracketed to a flanged valve while guaranteeing continued mechanical resistance. 2.The substantial adjustable travel of these products means the “face to face” tolerances of the equipment to be installed is no longer a concern. 3.Makes placing joint rings between flanges easier, even those with inserts 4.Available from DN 40 to DN 2000, with PFAs of 10, 16 and 25 bar

Dismantling joint for butterfly valve without flanges

1.Maximum adjustable travel of 50 mm when bracketed to butterfly valves without flanges.

2.Available from DN 40 to DN 1200, with PFAs of 10 and 16 bar.

| PN10 | PN16 | PN25 | |||||||||||||

| DN | L | D | K | H | STUD | L | D | K | H | STUD | L | D | K | H | STUD |

| 40 | 180 | 150 | 110 | 330 | M16X4 | 180 | 150 | 110 | 330 | M16X4 | 190 | 150 | 110 | 340 | M16X4 |

| 50 | 180 | 165 | 125 | 330 | M16X4 | 180 | 165 | 125 | 330 | M16X4 | 200 | 165 | 125 | 350 | M16X4 |

| 65 | 180 | 185 | 145 | 330 | M16X4 | 180 | 185 | 145 | 330 | M16X4 | 200 | 185 | 145 | 350 | M16X8 |

| 80 | 200 | 200 | 160 | 350 | M16X8 | 200 | 200 | 160 | 350 | M16X8 | 210 | 200 | 160 | 360 | M16X8 |

| 100 | 200 | 220 | 180 | 350 | M16X8 | 200 | 220 | 180 | 350 | M16X8 | 220 | 235 | 190 | 370 | M20X8 |

| 125 | 200 | 250 | 210 | 350 | M16X8 | 200 | 250 | 210 | 350 | M16X8 | 220 | 270 | 220 | 380 | M24X8 |

| 150 | 200 | 285 | 240 | 350 | M20X8 | 200 | 285 | 240 | 350 | M20X8 | 230 | 300 | 250 | 390 | M24X8 |

| 200 | 220 | 340 | 295 | 380 | M20X8 | 220 | 340 | 295 | 380 | M20X12 | 230 | 360 | 310 | 400 | M24X8 |

| 250 | 220 | 400 | 350 | 380 | M20X12 | 230 | 400 | 355 | 400 | M24X12 | 250 | 425 | 370 | 430 | M27X12 |

| 300 | 220 | 455 | 400 | 390 | M20X12 | 250 | 455 | 410 | 420 | M20X12 | 250 | 485 | 430 | 440 | M27X16 |

| 350 | 230 | 505 | 460 | 400 | M20X16 | 260 | 520 | 470 | 440 | M24X16 | 270 | 555 | 490 | 470 | M30X16 |

| 400 | 230 | 565 | 515 | 410 | M24X16 | 270 | 580 | 525 | 460 | M27X16 | 280 | 620 | 550 | 490 | M33X16 |

| 450 | 250 | 615 | 565 | 430 | M24X20 | 270 | 640 | 585 | 470 | M27X20 | 280 | 670 | 600 | 490 | M33X20 |

| 500 | 260 | 670 | 620 | 450 | M24X20 | 280 | 715 | 650 | 490 | M30X20 | 300 | 730 | 660 | 520 | M33X20 |

| 600 | 260 | 780 | 725 | 460 | M27X20 | 300 | 840 | 770 | 520 | M33X20 | 320 | 845 | 770 | 560 | M36X20 |

| 700 | 260 | 895 | 840 | 460 | M27X24 | 300 | 910 | 840 | 520 | M33X24 | 340 | 960 | 875 | 590 | M39X24 |

| 800 | 290 | 1010 | 950 | 500 | M30X24 | 320 | 1025 | 950 | 550 | M36X24 | 360 | 1085 | 990 | 630 | M45X24 |

| 900 | 290 | 1115 | 1050 | 500 | M30X28 | 320 | 1125 | 1050 | 560 | M36X28 | 380 | 1185 | 1090 | 660 | M45X28 |

| 1000 | 290 | 1230 | 1160 | 510 | M33X28 | 340 | 1255 | 1170 | 600 | M39X28 | 400 | 1320 | 1210 | 690 | M52X28 |

| 1200 | 320 | 1455 | 1380 | 570 | M36X32 | 360 | 1485 | 1390 | 650 | M45X32 | 450 | 1530 | 1420 | 780 | M52X32 |