| Product Name: | 90-315mm Electrofusion HDPE Fittings Repair Saddle For Gas Supply PN16 SDR11 PE100 | Application: | Gas,Water,Oil Etc |

|---|---|---|---|

| Specification: | PE100 PN16 SDR11 | Material: | PE100 Virgin Raw Material |

| Standard: | EN 1555-3:2010 | Port: | China Main Port |

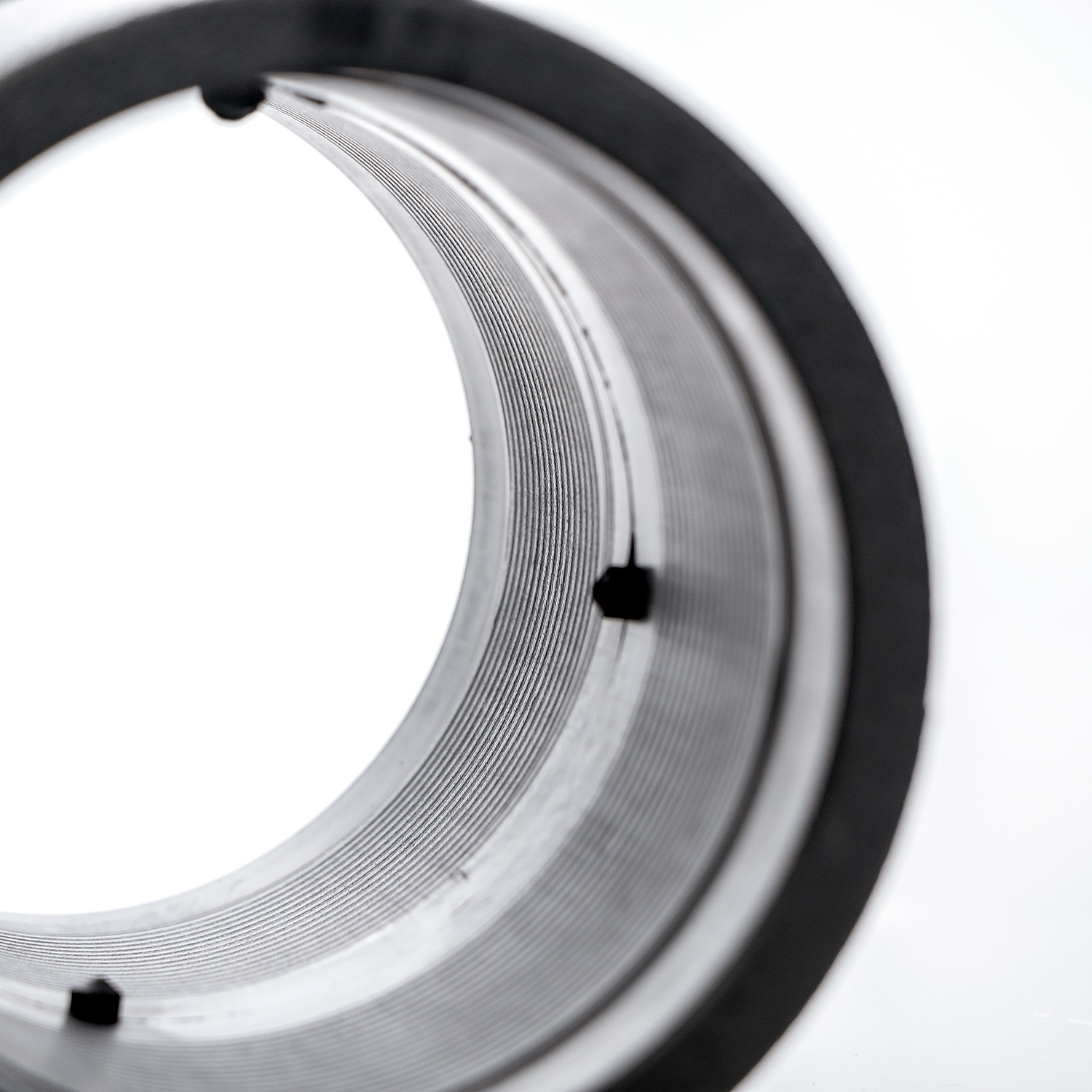

90-315mm Electrofusion HDPE Fittings Repair Saddle for Gas supply PN16 SDR11 PE100

Production Description of Electrofusion HDPE Rrpair Saddle

-Electrofusion HDPE fittings are welded by electrofusion machine to connect HDPE pipes together: After electrofusion welding machine plug in electricity and turn on, The copper wire buried inserted in electric fuse HDPE fittings are heated and make HDPE melt, Which joint HDPE pipe and fittings well.

Main reasons to Choose CHUANGRONG Electrofusion HDPE Fittings

1.Technical Support

In order to better serve our customers, we have documented a wide range of Expertise in production and installation of piping systems to support large and medium-sized projects. 2.Thoughtful Service CHUANGRONG, as China’s “GF”, we fully understand the needs of customers and provide customers with the most cost-effective solutions — one-stop product portfolio of HDPE pipe systems (HDPE pipes, fittings, welding machines and tools. Also for customers Provide high value-added services, 24 hours to answer customer questions. Our ultimate goal is to add value to our customers through professional, efficient and cost-effective solutions. Tailored solutions for customers. Combine our Expertise in developing and producing pipelines Systems, and deep industries And market knowledge, based on long-term Experience to provide customers with cost-effective solutions. 3.Environmental CHUANGRONG HDPE pipeline system integrates its environmental responsibility into its daily business activities. HDPE is a green environmental protection material, which can be recycled without causing pollution to the environment. We work hard to conserve natural resources and constantly strive to optimize the environmental performance of our products and how they used. 4.Cost-effective Highest cost performance Compared with traditional steel pipes, it is light and easy for workers to install and repair Low installation and maintenance costs Easy loading and transportation Suitable for non-excavation Production workshop & Equippments of Electrofusion HDPE Fittings

Own over 100 sets of injection molding machine; The largest(300,000g) domestic injection molding machine; Over 20 units hautomation robot; 8 sets automation Electrofusion HDPE fittings production system. Annual capacity of over 13000 tons which gives customers huge inventory support.

| specifications φD | L mm | A mm | H mm | φd mm |

| 90 | 145 | 154 | 68 | 4.7 |

| 110 | 145 | 160 | 60 | 4.7 |

| 160 | 190 | 230 | 78 | 4.7 |

| 200 | 190 | 235 | 90 | 4.7 |

| 250 | 190 | 300 | 65 | 4.7 |

| 315 | 190 | 300 | 75 | 4.7 |

| Test item | Standard | Conditions | Results | Unit |

| 1.Melt Flow Index | ISO1133 | 190°C & 5.0Kg 0.2-0.7 | 0.49 | g/10min |

| 2.Density | ISO1183 | @23°C ≥0.95 | 0.960 | g/cm3 |

| 3.Oxidation Induction Time | ISO11357 | 210°C >20 | 39 | Min |

| 4. Hydrostatic Pressure Test | ISO1167 | 80°C 165h, 5.4Mpa | Passed | |

| 5 Size Check | ISO3126 | 23°C | Passed | |

| 6 Appearance | Clean& Smooth | 23°C | Passed |

- The results according to test 1-3 are taken form the PE raw material supplier’s report.

- The results according to test 4-6 are taken from the internal test results of fittings sampled from the

- same batch as delivered fittings.

- Marking according EN 12201 – 3 and EN 1555 – 3.

- The pass/fail criteria are based on the requirements of the UNI EN 12201 and UNI EN 1555 standards.

1.Municipal water supply, gas supply and agriculture etc. 2.Commercial & Residential water supply 3.Industrial liquids transportation 4.Sewage treatment 5. Food and chemical industry 6. Replacement of cement pipes and steel pipes 7. Argillaceous silt, mud transportation 8. Garden green pipe networks

1.Municipal water supply, gas supply and agriculture etc. 2.Commercial & Residential water supply 3.Industrial liquids transportation 4.Sewage treatment 5. Food and chemical industry 6. Replacement of cement pipes and steel pipes 7. Argillaceous silt, mud transportation 8. Garden green pipe networks