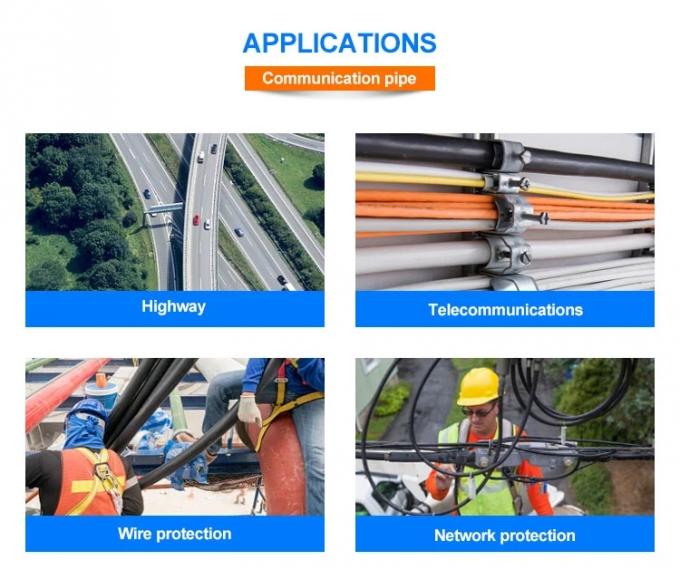

| roduct Name: | 100mm 89mm PE100 High Density Polyethylene Pipe For Cable Or Electricity Wire | Application: | For Cable Or Elctricity Wire |

|---|---|---|---|

| Material: | 100% Virgin Material PE100 | Specification: | DN63mm DN200mm DN315 PN16 SDR11 |

| Pipe Color: | Black With Orange Stripe | Pressure: | PN6 PN8 PN10 |

| Item | Index |

| Density (g/cm3) | 0.90-0.94 |

| Ring Stiffness(3%,Normal Tem,Kpa) | SN24 ≥24 SN32 ≥32 SN40 ≥40 |

| Flattening Test (50%) | No break,no crack. |

| Hammer Impact | No break,no crack. |

| Vicat Soften Temperature ( ℃) | ≥150 |

| Tensile Strength (%) | Pipe:≥25 ; Fusion Joint: ≥22.5 |

| Elongation at Break (%) | ≥400 |

| Flexural Strength (Mpa) | ≥36 |

| E straight tube series | Nominal outer diameter | Wall thickness | Ring stiffness | Material | Package length |

| 48.3mm | 2.2mm | ≤10 level | HDPE | 6 m / root | |

| 48.3mm | 2.5mm | ≥10 level | HDPE | 6 m / root | |

| 48.3mm | 3.0mm | ≥10level | HDPE | 6 m / root | |

| 48.3mm | 4.0mm | ≥15 level | HDPE | 6 m / root | |

| 60.3mm | 2.2mm | ≤10level | HDPE | 6 m / root | |

| 60.3mm | 2.5mm | ≤10level | HDPE | 6 m / root | |

| 60.3mm | 3.0mm | ≥10level | HDPE | 6 m / root | |

| 75mm | 2.2mm | ≤10level | HDPE | 6 m / root | |

| 75mm | 2.8mm | ≤10level | HDPE | 6 m / root | |

| 75mm | 4.0mm | ≥15 level | HDPE | 6 m / root | |

| 75mm | 5.0mm | ≥15 level | HDPE | 6 m / root | |

| 89mm | 2.8mm | ≤10level | HDPE | 6 m / root | |

| 89mm | 3.5mm | ≥10level | HDPE | 6 m / root | |

| 100mm | 2.8mm | ≤10level | HDPE | 6 m / root | |

| 100mm | 3.2mm | ≤10level | HDPE | 6 m / root | |

| 100mm | 3.5mm | ≥10level | HDPE | 6 m / root | |

| 100mm | 4.0mm | ≥15 level | HDPE | 6 m / root | |

| 110mm | 2.8mm | ≤10level | HDPE | 6 m / root | |

| 110mm | 3.2mm | ≤10level | HDPE | 6 m / root | |

| 110mm | 3.5mm | ≥10level | HDPE | 6 m / root | |

| 110mm | 4.0mm | ≥15 level | HDPE | 6 m / root | |

| 160mm | 5.0mm | ≥10level | HDPE | 6 m / root | |

| 160mm | 6.0mm | ≥15 level | HDPE | 6 m / root | |

| 160mm | 7.0mm | ≥15 level | HDPE | 6 m / root |

| Outside diameter(mm) | Thickness(mm) | Length(mm) | ||

| Ring stiffness (3% ) Normal temperature | ||||

| SN24 | SN32 | SN40 | ||

| 110 | 6 | 8 | 10 | 6000 |

| 160 | 10 | 12 | 14 | |

| 180 | 12 | 14 | 16 | 9000 |

| 200 | 14 | 16 | 18 | |

| 225 | 16 | 18 | 20 | 12000 |

| 250 | 18 | 20 | 22 | |

1. M-PP pipe has excellent electrical insulation.

2. M-PP pipe has higher thermal deformation temperature and low temperature impact performance.

3. M-PP pipe has higher tensile and compression resistance than HDPE.

4, M-PP pipe is light, smooth, frictional resistance is small, can be hot-melt butt joint.

5, M-PP tube long-term use temperature-5 ~ 70 ℃.

6. Construction instructions It is strictly forbidden to drop, hit, scratch, or expose to the sun during the transportation and construction of pipes.

The axis of the two pipes must be aligned during the hot-melt butt joint, and the end face cutting should be vertical and flat.

The processing temperature, time, pressure, and climate conditions are adjusted accordingly. The minimum bending radius of the pipe should be ≥75 pipe outer diameter.