Products Details

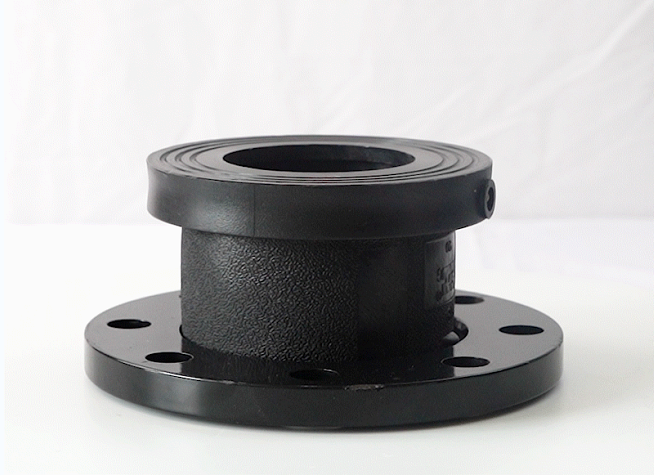

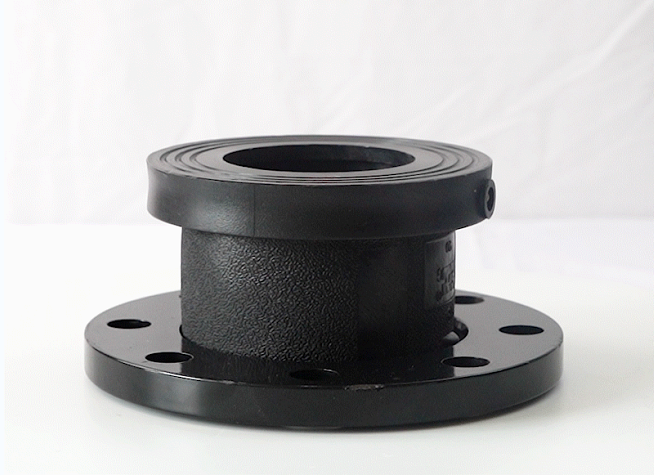

| Product Name: | Flange Plate OR Backing Ring For HDPE Electrofusion Fittings Flange Adapter For Gas And Water Supply PN16 SDR11 PE100 | Connection: | Flange Connection |

| Standard: | EN 12201-3:2011,EN 1555-3:2010 | Material: | Nylon Coated Flange Plate(PN16) |

| Pressure: | PN16 PN10 | Application: | Gas,Water,Oil Etc |

Flange plate OR Backing ring for HDPE Electrofusion Fittings Flange Adapter for Gas and Water supply PN16 SDR11 PE100

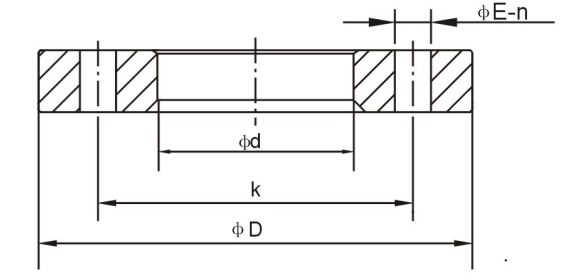

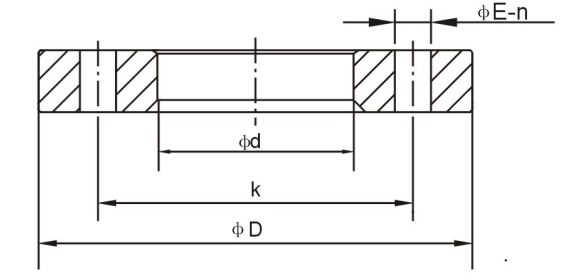

| Specification | ΦD | K | ΦE-n |

| PE | Steel | diameter | No. |

| 40 | 32 | 130 | 100 | 18 | 4 |

| 50 | 40 | 140 | 110 | 18 | 4 |

| 63 | 50 | 155 | 125 | 18 | 4 |

| 75 | 65 | 177 | 145 | 18 | 4 |

| 90 | 80 | 190 | 160 | 18 | 8 |

| 110 | 100 | 212 | 180 | 18 | 8 |

| 125 | 100 | 212 | 180 | 18 | 8 |

| 140 | 125 | 240 | 210 | 18 | 8 |

| 160 | 150 | 277 | 240 | 22 | 8 |

| 180 | 150 | 277 | 240 | 22 | 8 |

| 200 | 200 | 330 | 295 | 22 | 8 |

| 225 | 200 | 330 | 295 | 22 | 8 |

| 250 | 250 | 400 | 355 | 26 | 12 |

| 280 | 250 | 400 | 355 | 26 | 12 |

| 315 | 300 | 445 | 410 | 26 | 12 |

| 355 | 350 | 505 | 470 | 26 | 16 |

| 400 | 400 | 565 | 525 | 30 | 16 |

| 450 | 450 | 625 | 585 | 30 | 20 |

| 500 | 500 | 700 | 650 | 34 | 20 |

| 560 | 600 | 825 | 770 | 36 | 20 |

| 630 | 600 | 825 | 770 | 36 | 20 |

1.Cost-effective Highest cost performance Compared with traditional steel pipes, it is light and easy for workers to install and repair Low installation and maintenance costs Easy loading and transportation Suitable for non-excavation 2.Safety and Reliability Life span of at least 50 years Completely maintenance-free In all weather conditions Excellent chemical resistance Good impact and abrasion resistance 3.Flexiblity Multiple connection methods, suitable for electric melting, hot melting, socket, flange connection. Electrofusion is the most efficient, time-saving, and labor-saving welding method. CHUANGRONG provides high-, middle- and low-end brands of electric fusion welding machines to meet the various needs of customers. Including RITMO and CHUANGRONG Brand. 4.Sustainability Relatively low carbon footprint Fully recyclable, environmentally friendly materials 5.Professional Solution 1) Accept customer OEM production, large quantity customization requirements. 2) Technical support:Professional engineers and senior, special engineers provide technical support:More than 80 Technique personnel,20 Middle class engineer,8 Senior Engineers. 3)More than 100 sets injection molding machine and the largest (300,000g)domestic injection molding machine; Over 20 units of automation robot, 8 sets automation Electrofusion fittings production system. 4)Various type(Elbow,Coupler,Tee,End Cap,Saddle,Ball Valve etc) and completed specification(Ranged from 20-630 Electrofusion type) 5)Annual production capacity up to 13000 tons(More than 10 million pieces or more) 6.Technical Support The key factors of product quality are technical support and material selection Installed successfully. Our strong and efficient teamwork provides customers with the best solution in a timely manner: the sales team understands and understands the customer’s use and proposes suitable HDPE pipeline solutions and products. The production department coordinates the production plan to ensure the fastest delivery time. Engineers and technicians solve and provide technical product performance and technical support. 7.Customized services The team of CHUANGRONG pipeline system provides corresponding solutions according to customer needs: Various special solutions can be produced in small batches. Standardized processes ensure highest quality Personalized solutions for customers. 8.Environmentally CHUANGRONG HDPE pipeline system integrates its environmental responsibility into its daily business activities. HDPE is a green environmental protection material, which can be recycled without causing pollution to the environment. We work hard to conserve natural resources and constantly strive to optimize the environmental performance of our products and how they used.

1.Cost-effective Highest cost performance Compared with traditional steel pipes, it is light and easy for workers to install and repair Low installation and maintenance costs Easy loading and transportation Suitable for non-excavation 2.Safety and Reliability Life span of at least 50 years Completely maintenance-free In all weather conditions Excellent chemical resistance Good impact and abrasion resistance 3.Flexiblity Multiple connection methods, suitable for electric melting, hot melting, socket, flange connection. Electrofusion is the most efficient, time-saving, and labor-saving welding method. CHUANGRONG provides high-, middle- and low-end brands of electric fusion welding machines to meet the various needs of customers. Including RITMO and CHUANGRONG Brand. 4.Sustainability Relatively low carbon footprint Fully recyclable, environmentally friendly materials 5.Professional Solution 1) Accept customer OEM production, large quantity customization requirements. 2) Technical support:Professional engineers and senior, special engineers provide technical support:More than 80 Technique personnel,20 Middle class engineer,8 Senior Engineers. 3)More than 100 sets injection molding machine and the largest (300,000g)domestic injection molding machine; Over 20 units of automation robot, 8 sets automation Electrofusion fittings production system. 4)Various type(Elbow,Coupler,Tee,End Cap,Saddle,Ball Valve etc) and completed specification(Ranged from 20-630 Electrofusion type) 5)Annual production capacity up to 13000 tons(More than 10 million pieces or more) 6.Technical Support The key factors of product quality are technical support and material selection Installed successfully. Our strong and efficient teamwork provides customers with the best solution in a timely manner: the sales team understands and understands the customer’s use and proposes suitable HDPE pipeline solutions and products. The production department coordinates the production plan to ensure the fastest delivery time. Engineers and technicians solve and provide technical product performance and technical support. 7.Customized services The team of CHUANGRONG pipeline system provides corresponding solutions according to customer needs: Various special solutions can be produced in small batches. Standardized processes ensure highest quality Personalized solutions for customers. 8.Environmentally CHUANGRONG HDPE pipeline system integrates its environmental responsibility into its daily business activities. HDPE is a green environmental protection material, which can be recycled without causing pollution to the environment. We work hard to conserve natural resources and constantly strive to optimize the environmental performance of our products and how they used.

S-Shaped Trap,

Water supply valve,

Gas Supply Valve,

White PPR pipe for cold water,

Tee fitting,

Hdpe Water Pipe,

"PP ball valve for irrigation,

High quality PPR fittings,

mm Drainage Fittings,

Round head blue fittings,

1.Cost-effective Highest cost performance Compared with traditional steel pipes, it is light and easy for workers to install and repair Low installation and maintenance costs Easy loading and transportation Suitable for non-excavation 2.Safety and Reliability Life span of at least 50 years Completely maintenance-free In all weather conditions Excellent chemical resistance Good impact and abrasion resistance 3.Flexiblity Multiple connection methods, suitable for electric melting, hot melting, socket, flange connection. Electrofusion is the most efficient, time-saving, and labor-saving welding method. CHUANGRONG provides high-, middle- and low-end brands of electric fusion welding machines to meet the various needs of customers. Including RITMO and CHUANGRONG Brand. 4.Sustainability Relatively low carbon footprint Fully recyclable, environmentally friendly materials 5.Professional Solution 1) Accept customer OEM production, large quantity customization requirements. 2) Technical support:Professional engineers and senior, special engineers provide technical support:More than 80 Technique personnel,20 Middle class engineer,8 Senior Engineers. 3)More than 100 sets injection molding machine and the largest (300,000g)domestic injection molding machine; Over 20 units of automation robot, 8 sets automation Electrofusion fittings production system. 4)Various type(Elbow,Coupler,Tee,End Cap,Saddle,Ball Valve etc) and completed specification(Ranged from 20-630 Electrofusion type) 5)Annual production capacity up to 13000 tons(More than 10 million pieces or more) 6.Technical Support The key factors of product quality are technical support and material selection Installed successfully. Our strong and efficient teamwork provides customers with the best solution in a timely manner: the sales team understands and understands the customer’s use and proposes suitable HDPE pipeline solutions and products. The production department coordinates the production plan to ensure the fastest delivery time. Engineers and technicians solve and provide technical product performance and technical support. 7.Customized services The team of CHUANGRONG pipeline system provides corresponding solutions according to customer needs: Various special solutions can be produced in small batches. Standardized processes ensure highest quality Personalized solutions for customers. 8.Environmentally CHUANGRONG HDPE pipeline system integrates its environmental responsibility into its daily business activities. HDPE is a green environmental protection material, which can be recycled without causing pollution to the environment. We work hard to conserve natural resources and constantly strive to optimize the environmental performance of our products and how they used.

1.Cost-effective Highest cost performance Compared with traditional steel pipes, it is light and easy for workers to install and repair Low installation and maintenance costs Easy loading and transportation Suitable for non-excavation 2.Safety and Reliability Life span of at least 50 years Completely maintenance-free In all weather conditions Excellent chemical resistance Good impact and abrasion resistance 3.Flexiblity Multiple connection methods, suitable for electric melting, hot melting, socket, flange connection. Electrofusion is the most efficient, time-saving, and labor-saving welding method. CHUANGRONG provides high-, middle- and low-end brands of electric fusion welding machines to meet the various needs of customers. Including RITMO and CHUANGRONG Brand. 4.Sustainability Relatively low carbon footprint Fully recyclable, environmentally friendly materials 5.Professional Solution 1) Accept customer OEM production, large quantity customization requirements. 2) Technical support:Professional engineers and senior, special engineers provide technical support:More than 80 Technique personnel,20 Middle class engineer,8 Senior Engineers. 3)More than 100 sets injection molding machine and the largest (300,000g)domestic injection molding machine; Over 20 units of automation robot, 8 sets automation Electrofusion fittings production system. 4)Various type(Elbow,Coupler,Tee,End Cap,Saddle,Ball Valve etc) and completed specification(Ranged from 20-630 Electrofusion type) 5)Annual production capacity up to 13000 tons(More than 10 million pieces or more) 6.Technical Support The key factors of product quality are technical support and material selection Installed successfully. Our strong and efficient teamwork provides customers with the best solution in a timely manner: the sales team understands and understands the customer’s use and proposes suitable HDPE pipeline solutions and products. The production department coordinates the production plan to ensure the fastest delivery time. Engineers and technicians solve and provide technical product performance and technical support. 7.Customized services The team of CHUANGRONG pipeline system provides corresponding solutions according to customer needs: Various special solutions can be produced in small batches. Standardized processes ensure highest quality Personalized solutions for customers. 8.Environmentally CHUANGRONG HDPE pipeline system integrates its environmental responsibility into its daily business activities. HDPE is a green environmental protection material, which can be recycled without causing pollution to the environment. We work hard to conserve natural resources and constantly strive to optimize the environmental performance of our products and how they used.