| Usage: | Welding | Working Range: | 280-450/315-500/400-630 |

|---|---|---|---|

| Power Supply: | 380/415 | Warranty: | One Year |

| Port: | China’s Major Port | Plate Tempreture: | 170-250 Celsius |

| Model | CRDH 450 | CRDH 500 | CRDH 630 |

| Range(mm) | 280/315/355/400/450 | 315/355/400/450/500 | 400/450/500/560/630 |

| The Heating Plate Temperature | 170℃-250℃(±5℃)Max270℃ | 170℃-250℃(±5℃)Max270℃ | 170℃-250℃(±5℃)Max270℃ |

| Power Supply | 8.7KW | 10.3KW | 12.35KW |

| Total Weight | 388kg | 400kg | 617kg |

| Optional Accessory | Stub end holder,Crane and special inserts | ||

| Instruments:Timer Pressure gauge Thermometer | Make sure they are in good working condition. | |

| Milling cutter | Make sure that it is in good working condition. Make sure the blades are sharp enough. | |

| Heating plate | Make sure the Teflon surface is free from damage. Use a digital thermometer to check that the temperature reached corresponds to the temperature value set. | |

| Joint | Test by doing experimental welding before use. | |

The CRDH is an on-site welding machine equipped with a heating element for butt-welding of pipes and/or fittings made of Polyethylene (PE), Polypropylene (PP) and other thermoplastic materials intended for carrying combustible gas, water and other fluids under pressure.

The CRDHcan weld PE100 with the “Dual Pressure” method.

The use of this welding machine is only allowed to trained staff having the qualifications required by the regulations in force.

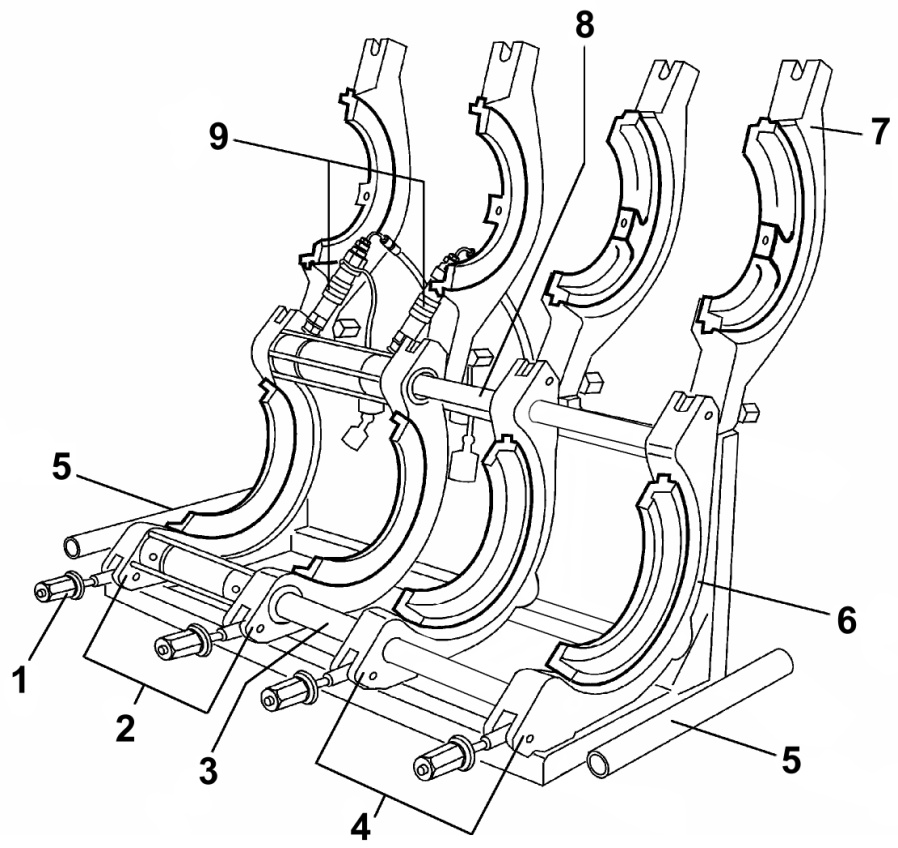

MACHINE BODY

- Screw nut for clamps closure

- Movable carriage

- Lower piston rod

- Fixed carriage

- Handling points

- Lower jaw

- Upper jaw

- Upper piston rod

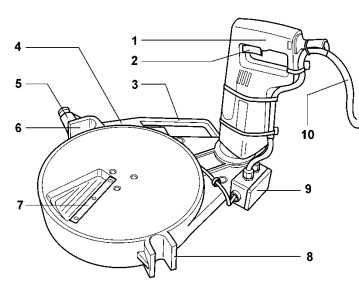

MILLING CUTTER

1. Handgrip

2. Fork for upper piston rod

3. Fork for lower piston rod

4. Motor

5. Blade

6. Fuse carrier

7. Motor starting button

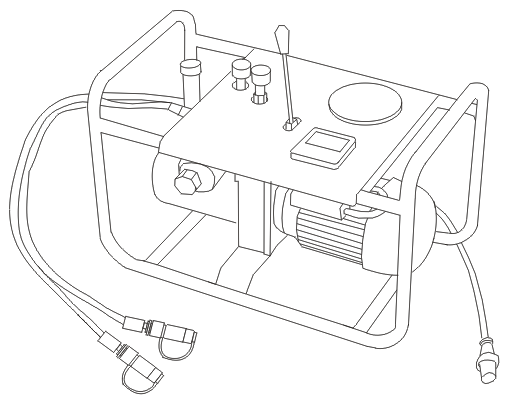

ELECTROHYDRAULIC GEARCASE

ELECTROHYDRAULIC GEARCASE - Discharge pressure valve

- Lever for proportional distributor

- Maximum pressure valve

- Oil pressure gauge

- Timer

- Quick connector

- Power supply in-let

- handgrip

- Tank cap

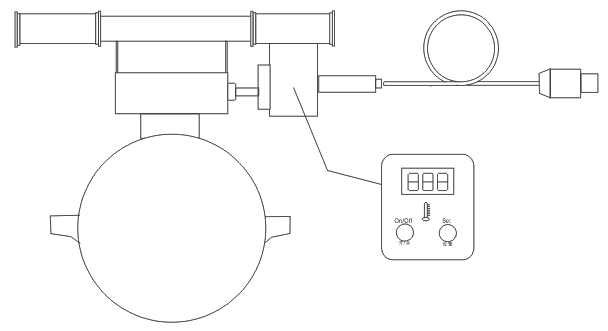

HEATING PLATE

HEATING PLATE 1. Handgrip

2. Heating plate